Businesses must embrace new ideas and prepare their employees for the future as technology shifts the workplace. This means bringing together a skilled and adaptable workforce ready to embrace new technologies.

At a time when technology has made much office work easier and more efficient, HR departments at most companies still rely on the same old manual processing and management that they did decades ago.

“Fortunately, this is starting to change with the release of new software platforms specifically designed for streamlining the management of employees. The most comprehensive of these software suites are known as human capital management programs, which provide tech solutions for nearly all HR needs concentrated in one place.”

ERIC FOODIM, CEO, LBMC EMPLOYMENT PARTNERS

Navigating Government Regulations

Businesses also need to keep up with regulatory requirements, such as labor laws and minimum wage increases, in addition to workforce development. Competitive pay, flexible hours, and benefits can help companies meet these requirements while bringing in top talent.

Businesses handling regulated goods like drugs, alcohol, and tobacco must keep compliant and streamline their supply chain to prevent interruptions.

“Understanding and utilizing tax credits can have a substantial impact on profitability in the retail, manufacturing, and distribution industries. LBMC’s expertise in state and local tax (SALT) services can assist these businesses in optimizing their tax positions and increasing cash flow.”

LEIGH ANN VERNICH, SENIOR MANAGER, TAX, LBMC, PC

Competing with Online-Only Retailers

Online retailers are growing, putting more pressure on brick-and-mortar stores to stay competitive. Using options like buy-online, pick-up-in-store (BOPIS) and AR-enhanced shopping experiences help traditional retailers stand out.

Using AI for personalized marketing enhances customer engagement in both online and offline spaces. With automation changing industries, businesses need to train their staff on using AI and robotics.

By 2030, automation could push 375 million workers to change jobs, says McKinsey. Businesses must grow their workforce to stay competitive in an automated world.

Staff Development and Retention

Keeping skilled employees is essential in a competitive job market. Companies with positive cultures, flexible work options, and clear career paths do a better job of attracting and retaining top talent. McKinsey notes that businesses with good employee engagement can cut turnover by up to 24%.

Adopting retention strategies that emphasize flexibility, continuous learning, and professional development is essential for businesses to attract and retain a skilled workforce for the future.

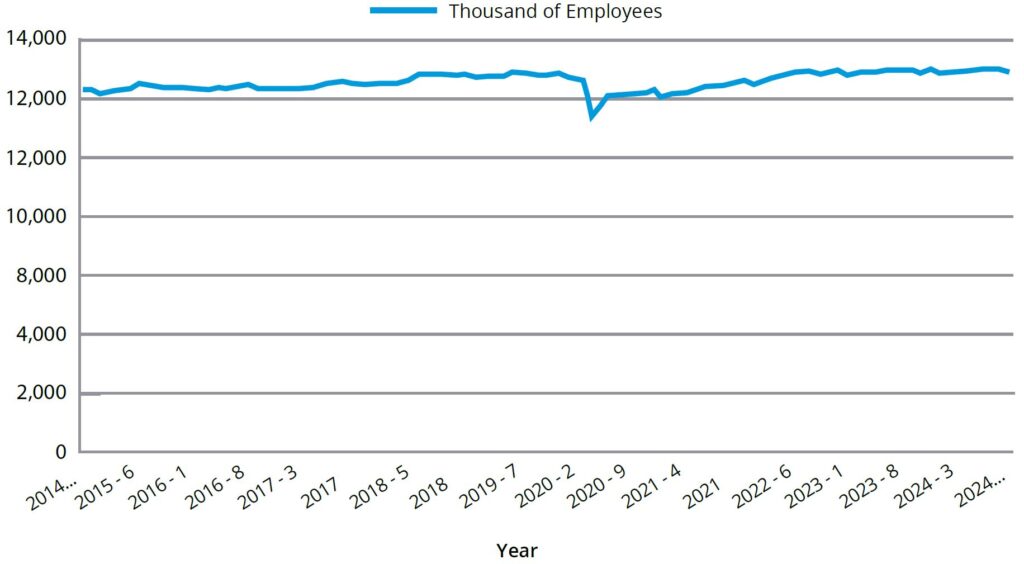

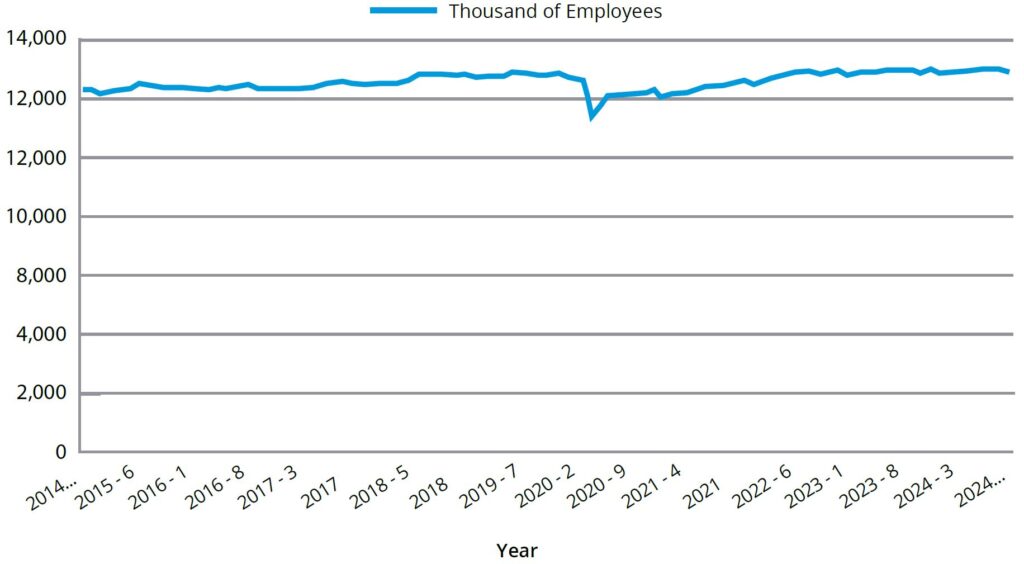

US Manufacturing Sector Employment

Source: Vertical IQ, Bureau of Labor Statistics

Application of Team Tools and Online Training

Businesses are using online training and collaborative tools to support their workforce and improve communication and skills in blended workforce settings.

These tools enable employees to quickly adjust to new technologies and build important skills for handling advanced systems. Remote training programs can boost productivity by up to 20%, according to McKinsey, making them essential for a solid workforce strategy.

“Investments in technology and people are intertwined—and companies that realize they can’t have one without the other are able to attract and retain higher-performing employees. Over the past few years, many companies have accelerated moving to new platforms as many weren’t prepared to shift to a remote work environment. Moving to these cloud-based solutions helps eliminate the cost of equipment, network administration, and security concerns that are real costs to a company that houses and maintains their technology infrastructure onsite.”

BRYAN WILTON, CEO AND PRESIDENT, LBMC TECHNOLOGY SOLUTIONS